Meet Omega Thermo Products. The leader in laser plate technology.

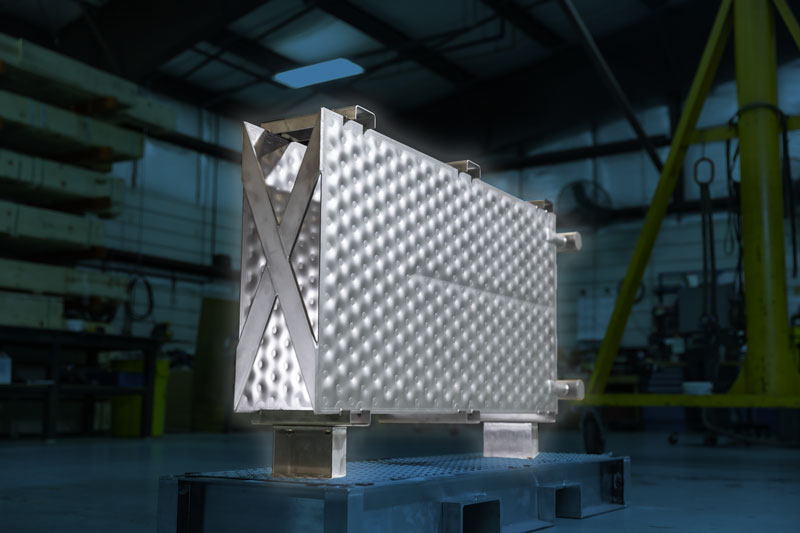

R.W. Fernstrum has partnered with Omega Thermo Products to bring you laser plate technology. Laser Plates are heat exchanger plates that can be used in many ways for closed-circuit heating and cooling. As the inventor of the laser welding machine for these Laser Plates, Omega Thermo Products has an unprecedented amount of experience in the production of Laser Plate heat exchangers.

Design Features

What is a Laser Plate?

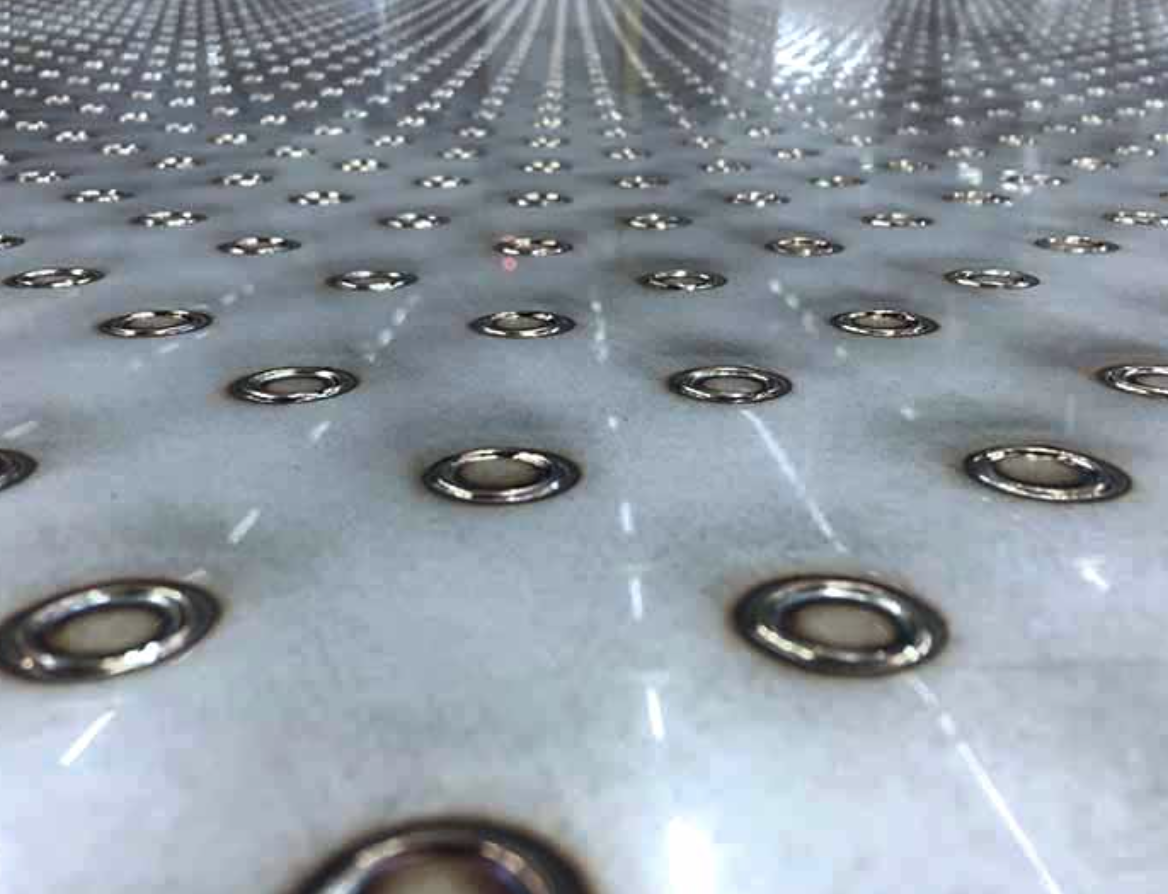

A Laser Plate consists of two sheets (stainless steel, titanium, exotic metals) that are welded together by welding a circle pattern with Omega’s laser welding machines. At the edges of the Laser Plate, a contour is welded to create a pressure-tight barrier. The plates are inflated to create a hollow space through which engine water coolant can flow.

Design

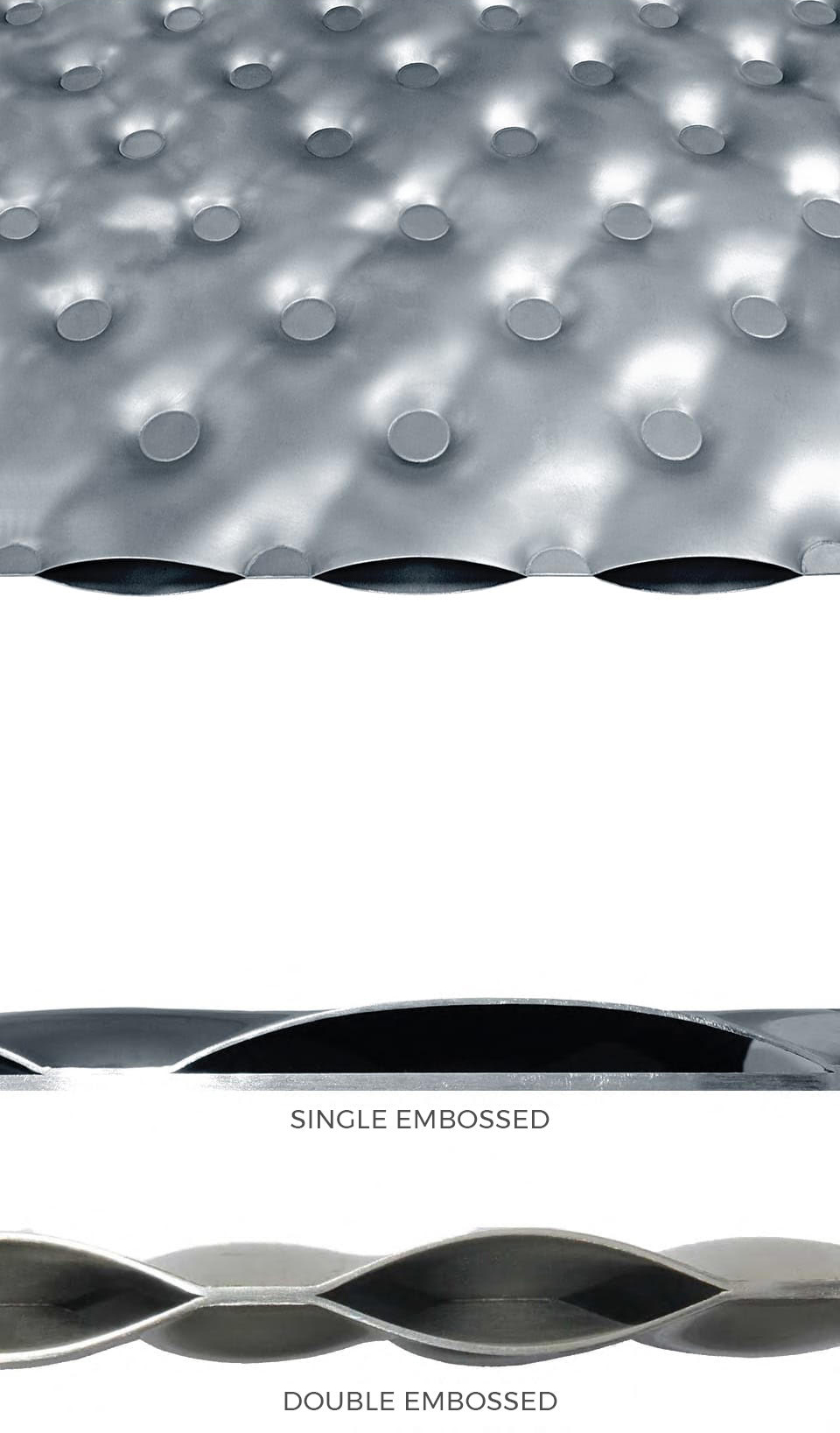

A Laser Plate design is always custom-made. At first, we look at your desired specifications. For applications requiring immersion plates, we recommend double-embossed plates (the plates are of the same thickness and both sides have the pillow pattern). For applications requiring that the plate itself is integrated into the wall of a pipe, decking, or storage tank, we recommend single embossed plates (the plates are of different thicknesses and only the thinner plate has the pillow pattern). You will receive the plate inflated and if required, assembled as a complete heat exchanger.

The welding patterns, plate cut-outs and plate shapes can all be adjusted to meet your specific application needs.

Advantages

- • Cost-effective due to low welding costs.

- • Thinner materials can be used, saving you on material costs.

- • The Laser Plate welding pattern guarantees high turbulence and high overall heat transfer coefficients.

- • Reduced deposition (algae, lime, etc.) due to this higher turbulence (less fouling).

- • Due to the low volume in the plate, lower volumes of heating/cooling fluid needs to be circulated. As a result, less pump capacity is required.

- • By working with laser welding machines that are CNC-programmed, all desired shapes, recesses, fastening points, and connections are possible. This also provides greater control over the bond between the plates.

Material Options

Immersion Plates Pillow Plates

Immersion Plates Pillow Plates

The material type, grade, and thicknesses depends on your desired application and capacity.

We are able to manufacture Laser Plates from a variety of metals including: stainless steel:

- • Austenitic material (304, 304L, 316, 316L, 317, 321)

- • (Super) duplex materials (2205, 2507, 2304, LDX-2101)

- • Nickel alloys (Nickel, Hastelloy, Inconel)

- • Titanium

Thickness single embossed

- • 22ga on 14ga

- • 22ga, 20ga on 12ga

- • 22ga, 20ga, 18ga on 10ga

- • 20ga, 18ga, 16ga on 7ga/ 3/16”

- • 18ga, 16ga, 14ga on 1/4″

- • 18ga, 16ga, 14ga on 5/16″

- • 16ga, 14ga on 3/8″

- • 16ga, 14ga on 1/2″

Thickness double embossed

- • 22ga

- • 20ga

- • 18ga

- • 16ga

- • 14ga

- • 12ga

- • 11ga

- • 10ga

Pressure

Our Laser Plates can handle a pressure of more than 1500 psi, depending on the required design temperature. If you have specific requirements, please let us know. Omega’s standard design pressure is 150 psi at 400/-20 °F.