In the box cooling. Out of the box thinking.

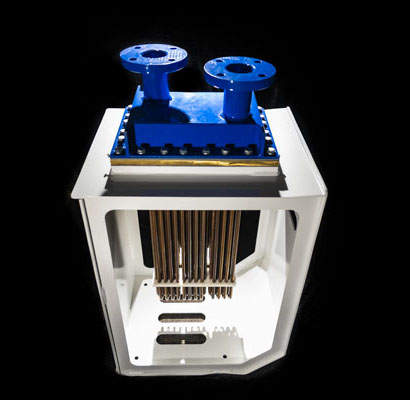

R.W. Fernstrum & Company has partnered with WEKA Marine to manufacture and sell boxcoolers, providing customers with the latest cooling solutions. The WEKA Boxcooler® is a compact, closed circuit cooling system that is mounted in a sea chest within the confines of the vessel’s hull, offering excellent protection from submerged obstacles.

Design Features

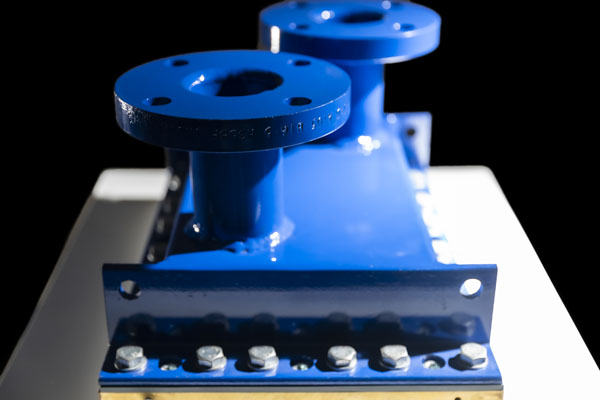

WEKA Protector Type T and WEKA GUARD

Exclusive to WEKA Boxcoolers are the WEKA Protector Type T and WEKA Guard. This equipment helps to minimize potential damage to the units and hull from stray electrical currents and galvanic corrosion. The WEKA Protector Type T also allows the copper-nickel to maintain its anti-fouling capabilities, protecting the tubes from marine growth.

Isolation

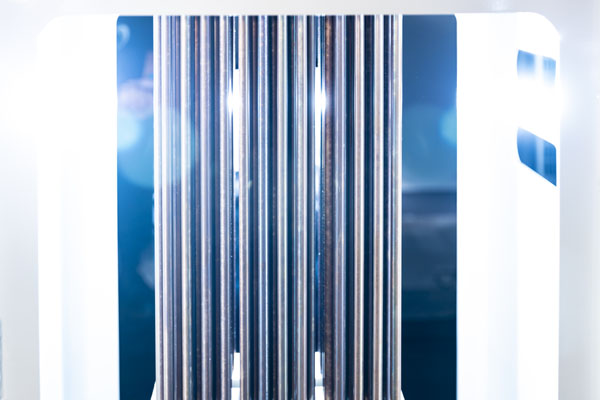

WEKA boxcoolers are constructed to be completely isolated from the hull during installation and in operation. Isolation from the ship’s hull combined with the WEKA Protector Type T allows the copper-nickel to maintain its anti-fouling capability.

Stepped Boxcooler

A WEKA Boxcooler can be engineered to accommodate tight spaces by stepping the unit.

Removable Bonnet

The bonnet can be removed from the boxcooler while the ship is still in the water.

Installation Options

Bottom Mounted Boxcooler

WEKA Boxcoolers have been successfully applied to the bottom mount applications, such as repower projects or when additional equipment requires cooling. In most cases, a boxcooler is installed in a top down fashion by lowering the unit into the mounting frame and welding the unit to the top of the sea chest. In a bottom mount application, a special top sea chest plate is pre-manufactured and secured to the unit’s mounting frame. The entire assembly is lifted from the bottom of the vessel through a hole cut in the hull and sea chest. The boxcooler is then fitted into the top of the sea chest and welded into place.

A boxcooler is installed one of two ways, athwartship or longitudinal.

A boxcooler is installed one of two ways, athwartship or longitudinal.

The sea chest requires careful planning. The inlet and outlet slots of the sea chest must provide a constant flow of seawater over the boxcooler’s tubes. The inlet slots are located at the base of the sea chest and should be positioned transversely to the outlet slots on the side of the sea chest. The outlet slots should be positioned as close to the top of the sea chest as possible. The outlet slots must always remain below the waterline, even when the vessel is in a light draft condition. Please refer to the installation manual for guidelines on slot quantity and sizing.

Material Options

90/10 Copper-Nickel

WEKA Boxcoolers are constructed using uncoated 90/10 copper-nickel tubing. This alloy does not require a protective coating or ICAF (Impressed Current Anti-Fouling) system due to its inherent corrosion resistance to seawater and natural anti-fouling capabilities. To protect the uncoated boxcoolers against potential stray current corrosion, a WEKA GUARD and WEKA Protector Type T system is applied. This exclusive design is successfully utilized in hundreds of vessels in fresh and saltwater applications worldwide.

Configuration Options

Single or Multiple Heat Sources

A boxcooler can be designed to support single or multiple heat sources with one unit.