GRIDCOOLER Configuration Options

The GRIDCOOLER® Keel Cooler is sized to meet your engine’s cooling requirements and operating environment. Our team will work with you to recommend features to optimize the functionality of your cooling system. The following examples show a few of the more common configurations. Additional configurations are available upon request.

Fernstrum offers two types of surfaces on the interior of the copper-nickel tubing, smooth or enhanced. The enhanced surface, a Fernstrum exclusive, is a truncated cone pattern on the interior of the tube generating greater heat transfer. Compared to a smooth-walled tube, the enhanced tube increases the heat transfer capability by up to 30 percent. This is especially true in applications where glycol solutions are utilized. The improvement in efficiency may reduce the number or size of the units required for an application. Note: The interior surface of the tubing is determined based on your cooling requirements.

Stacked

When faced with limited space or larger cooling requirements, a stacked GRIDCOOLER® Keel Cooler reduces the footprint of the keel cooler while providing greater heat transfer. The design is ideal for cooling larger engines, reducing the number of units required, or fitting into an existing application in the case of repowering.

Angled Tube

An angled tube GRIDCOOLER Keel Cooler optimizes the heat transfer for side-mounted zero knot or stationary applications. The design exploits the natural convection current created by the heat exchanger. The unique position and angle of the tubes are crafted to maximize the flow of raw water between the tubes. This configuration also resists the collection of silt and other debris from building up on the unit.

The angled tube GRIDCOOLER® Keel Cooler’s tubes are positioned to enhance and exploit the natural convection current generated by the heat exchanger.

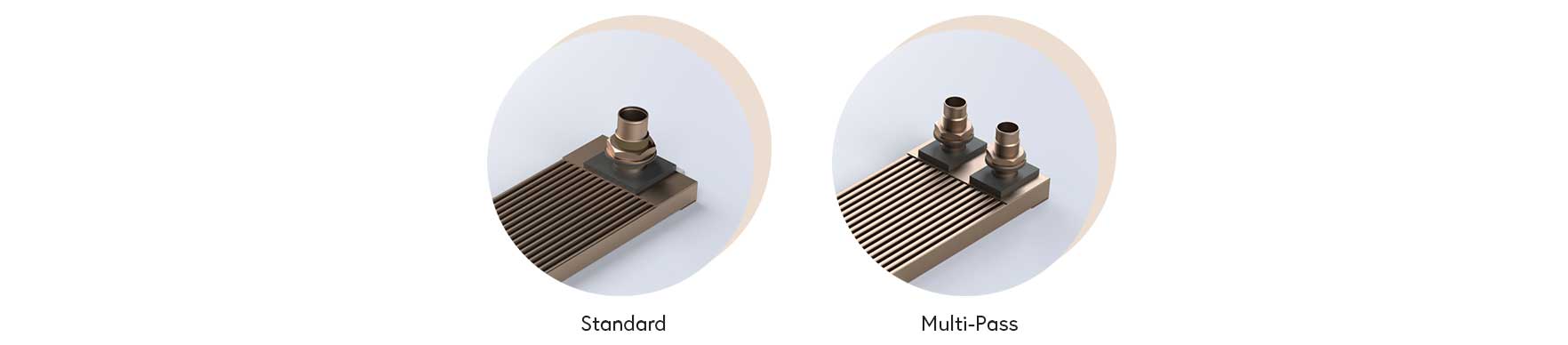

Fernstrum offers a range of single and multi-pass designs to help optimize your cooling solution. These designs maximize the efficiency of the engine coolant flow, allowing for a more compact solution.

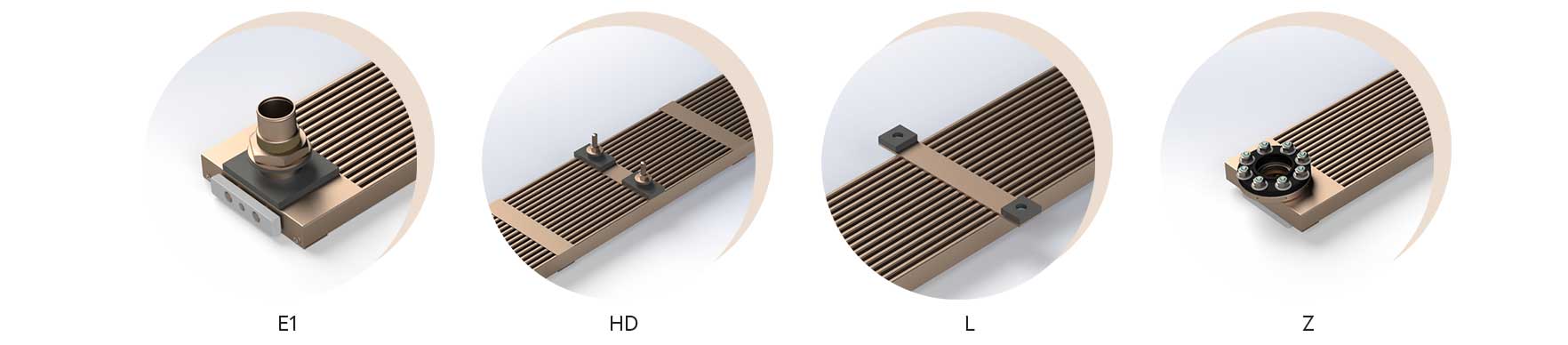

E1 Option

E1 Option units place the zinc anodes and drain plugs on the end of the keel cooler reducing the hull projection; a benefit to high speed craft and fishermen when entanglement of nets and/or lines is a concern.

HD Option

HD Option stiffener plates can be added to units providing additional support to prevent tubes from bowing, bending, or vibrating from the impact of heavy seas. These plates do not have additional mounting points. The HD Option is ideally suited for applications where the vessel is operating in heavy pounding seas, strong currents, or the keel cooler is positioned near the bow of the vessel.

L Option

L Option support plates are designed to minimize intermediate support bolt hull penetrations. These support plates extend beyond the keep cooler side tubes, providing additional securing options. This feature is especially useful in retrofitting a keel cooler to an existing vessel.

Z Option

Z Option flanges relocate the connecting and mating points to the hull’s exterior, eliminating hull penetrations. The typical through-hull nozzle mounting connections are replaced with a flange. Mating flanges are provided in carbon or stainless steel. Additional mounting hardware is also supplied for isolation. This design is ideal for installations where mounting hardware cannot be easily accessed from the interior of the hull, easing installation on double-hulled vessels and may eliminate the need for cofferdams. L Option support plates are standard in this configuration.